-

Tel:

Tel: 86-0577-67999969

-

Fax:

Fax: 86-0577-67988805

-

E-mail:

E-mail:

Heat conduction oil permeability is extremely strong medium: temperature range - 29-400 ℃, prevent closed system of medium loss and environmental pollution;

Vacuum system: packing for special occasions, strictly to prevent air flow backward cause pipe vacuum failure;

Steam kind of medium, prevent leakage cause heat loss and safety accident;

Chlorine, hydrogen, HF acid, phosphates, ammonia water poisonous medium: prevent medium leakage cause pollution of the environment and safety accident.

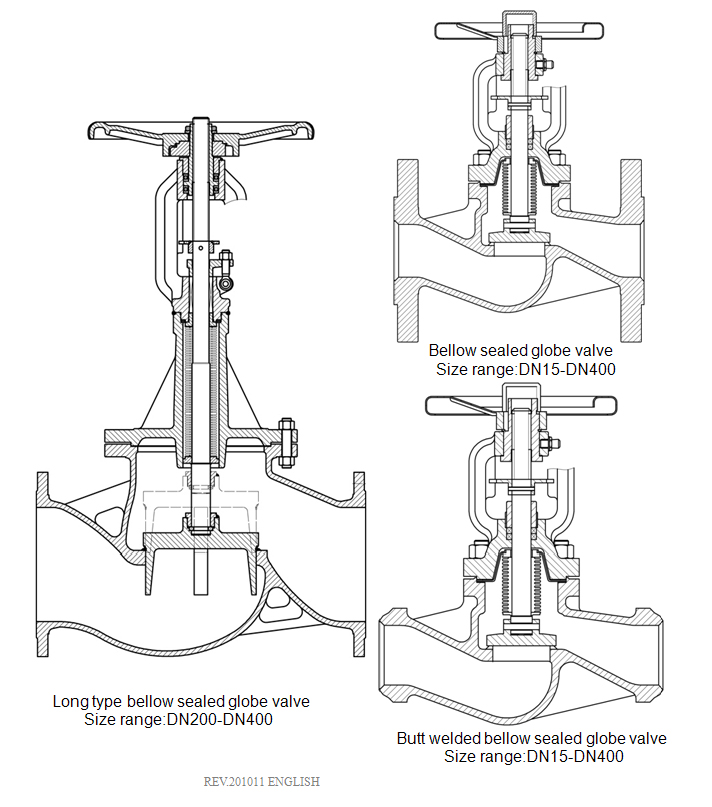

VCEN Product DIN standard of the design-Bellow seal globe valve

Design standard :EN13709,EN1984.

Bellows design standards :MSS SP117.

Face to face with standards :EN558-1.

Flanged with standards:EN1092-1

Butt welded with standards :EN12627.

pressure-temperature rating :EN12516

Test with standards:EN12266

VCEN Product ANSI standard of the design-Bellow seal globe valve

Design standard : BS1873,API602.

Bellows design standards :MSS SP117.

Face to face with standards :ASME B16.10.

Flanged with standards:ASME B16.5.

Butt welded with standards :ASME B16.25.

pressure-temperature rating :ASME B16.34.

Test with standards:API598,API6D

VCEN Product ANSI standard of the Design-Bellow seal gate valve

Design standard :API600,API6D,API602.

Bellows design standards :MSS SP117.

Face to face with standards :ASME B16.10.

Flanged with standards:ASME B16.5.

Butt welded with standards :ASME B16.25.

pressure-temperature rating :ASME B16.34.

Test with standards:API598,API6D

Bellow sealed globe valve

User manual

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings. Please contact us in case of problems which cannot be solved by reference to the operating instructions.

They are binding on the transport, storage, installation, operation, maintenance and repair.

The notes and warnings must be observed and adhered to:

- Handling and all work must be carried out by expert personnel or all activities must be supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to monitor the personnel.

- In addition, current regional safety requirements must be applied and observed when taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives.

2.0 Notes on possible dangers

2.1 Significance of symbols

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION!” describe practices, a failure to comply with which can result in serious injury or danger of death for users or third parties or in material damage to the system or the environment. It is vital to comply with these practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating and maintenance instructions as well as technical data (in the operating instructions, product documentation and on the device itself) must also be complied with to the fullest extent in order to avoid faults which in turn can cause serious injury to persons or damage to property.

3.0 Storage and transport

|

ATTENTION! - Protectagainst external force (like impact, vibration, etc.). - Valvemountings such as actuators, handwheel, hoods must not be used to take external forces. - Suitable materials handling and liftingequipment should be used. -The valve shall bestored indoor with dry and well-ventilated environmentat -20°C to +65°C., the ends of the port shall be plugged by covers. -The valve stored foralong time shall be checked periodically and cleaned to be free from stain。Especially clean thesealing ring to protect sealing surface against damage, and coatcorrosion -resistant oil on the machined surface. -If the stored timeexceeds 12 months,thevalve shall be tested to ensure structural and functional integrity. A recordis needed. -The paint is a base coat to protect againstcorrosion during transportation and storage. Do not damage paint protection. |

4.1 Scope of applications

Valves are used for “shut-off and/or throttling of medium”.

-This series valves are designed and manufactured in accordance with EN13709.

-The relevant standard is as follows:

-EN12266-1 Industrial valves, testing of valve, pressure tests, test procedures and acceptance criteria. mandatory requirements。

-EN12266-2 Industrial valves, testing of valve, pressure tests, test procedures and acceptance criteria. Supplementary requirements。

-EN 558-1 Industrial valves-face-to-face and centre-to-face dimensions of metal valves for use in flanged pipe systems-part 1:PN-designated valves

-EN12627 Industrial valve—butt welding ends for steel valves.

-EN1092 Flanges and their joints-circular flanges for pipes. valves. fittings and accessories, PN designated-part 1:steel flanges

-MSS-SP 117 Bellows Seals for Globe and Gate Valves

|

ATTENTION! -Refer to the data sheet for applications,limits on use and possibilities. - Certainmedium require or preclude the use of special materials. - The valves are designedfor standard operating conditions. If conditions exceed these requirements,e.g. aggressive or abrasive medium, the operator should state the higherrequirements when ordering. |

The information complies to the Pressure Equipment Directive 97/23/EC.

It is the responsibility of the machine planner to ensure compliance.

The special markings on the valve must be taken into account.

Refer to the catalogue sheet to see which materials are used in standard versions.

Please contact the manufacturer if you have any questions.

4.2 Operating principles

-The valve is closed by turning the hand wheel clockwise.

|

ATTENTION! Do not use the unsuitabletools to increase the torque on the handwheel. |

-The valve stem is sealed by a bellow and an outer safety stuffing box.the packing is PTFE or graphite.

-Tighten the safety stuffing box if required.

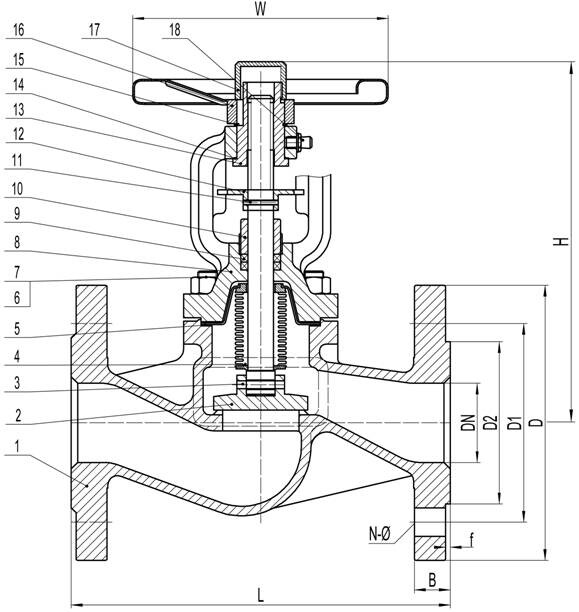

4.3 Diagram

4.4 Technical data

-Material list(see fig. ):

|

Table3.Material specification-DN15-DN200 |

|||||||||||

|

POS |

Detail |

carbon steel 3EO |

Alloy steel 5EO |

stainless steel |

|||||||

|

-10℃ till 400℃ |

-10℃ till 530℃ |

-20℃ till 200℃ |

|||||||||

|

1 |

Body |

GS-C25(1.0619) |

1.7357(WC6) |

CF8(1.4308) |

CF8M(1.4408) |

||||||

|

2 |

Disc |

C22.8 |

1.7357(WC6) |

F304 |

F316 |

||||||

|

|

Seat |

13Cr |

Stelite |

17Cr |

Stelite |

17Cr |

Stelite |

18Cr |

Stelite |

||

|

3 |

Pin |

SS304 |

SS304 |

SS304 |

SS304 |

||||||

|

4 |

Pin |

X20Cr13 |

X20Cr13 |

F304 |

F316 |

||||||

|

5 |

Gasket |

SS304+Graphite |

SS304+Graphite |

SS304+Graphite |

SS316+Graphite |

||||||

|

6 |

Bellows |

SS304 |

SS316L |

SS304 |

SS316L |

SS304 |

SS316L |

SS316L |

|||

|

7 |

Bolt |

ASTM A193 B7 |

1.7709 |

ASTM A193 B8 |

ASTM A193 B8M |

||||||

|

8 |

Nut |

ASTM A194 2H |

1.7709 |

ASTM A193 8 |

ASTM A193 8M |

||||||

|

9 |

Bonnet |

GS-C25(1.0619) |

1.7357(WC6) |

CF8(2C1) |

CF8M(2C2) |

||||||

|

10 |

Packing |

Graphite |

Graphite |

Graphite/PTFE |

Graphite/PTFE |

||||||

|

11 |

Gland Nut |

X20Cr13 |

X20Cr13 |

F304 |

F316 |

||||||

|

12 |

Guide |

C22.8 |

C22.8 |

F304 |

F316 |

||||||

|

13 |

Pin |

CK25 |

CK25 |

F304 |

F316 |

||||||

|

14 |

Stem nut |

GGG40.3 |

GGG40.3 |

GGG40.3 |

GGG40.3 |

||||||

|

15 |

Lock nut |

CK22 |

CK22 |

SS304 |

SS304 |

||||||

|

16 |

HandWheel |

C22.8 |

C22.8 |

C22.8 |

C22.8 |

||||||

|

17 |

circlip |

65Mn |

65Mn |

SS304 |

SS304 |

||||||

|

18 |

Nozzle |

SS304 |

SS304 |

SS304 |

SS304 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

- Principal dimensions(see fig. ):

|

DN |

L |

H (close) |

Stroke |

Weight(kg) |

Kv |

||

|

Pn16 |

Pn25 |

Pn40 |

|||||

|

15 |

130 |

200 |

8 |

4 |

4 |

4 |

4.6 |

|

20 |

150 |

205 |

8 |

4.6 |

4.6 |

4.6 |

8.0 |

|

25 |

160 |

210 |

10 |

5.5 |

5.5 |

5.5 |

13.2 |

|

32 |

180 |

215 |

10 |

7 |

7 |

7 |

21.0 |

|

40 |

200 |

225 |

15 |

9 |

9 |

9 |

33.0 |

|

50 |

230 |

230 |

15 |

11 |

11 |

11 |

51.0 |

|

65 |

290 |

245 |

18 |

15 |

15.5 |

15.8 |

83.0 |

|

80 |

310 |

270 |

22 |

19.8 |

21.5 |

21.8 |

133.0 |

|

100 |

350 |

340 |

28 |

33.2 |

37.1 |

37.5 |

205.0 |

|

125 |

400 |

380 |

33 |

48.6 |

55 |

55 |

315.0 |

|

150 |

480 |

430 |

40 |

67.2 |

78 |

78.5 |

454.0 |

|

200 |

600 |

575 |

55 |

121.50 |

145 |

154 |

780.0 |

|

250 |

730 |

730 |

65 |

228 |

245 |

265 |

1285.0 |

|

300 |

850 |

800 |

80 |

369 |

388 |

410 |

1805.0 |

|

350 |

980 |

940 |

95 |

610 |

660 |

690 |

2225.0 |

|

400 |

1100 |

1065 |

125 |

800 |

850 |

870 |

2906.0 |

- Pressure-temperature-ratings:

Material:1.0619

|

PN |

RA |

50°C |

100°C |

150°C |

200°C |

250°C |

300°C |

350°C |

375°C |

400°C |

|

16 |

15.6 |

14.9 |

13.6 |

12.7 |

11.4 |

10.4 |

9.4 |

8.8 |

8.6 |

8.4 |

|

25 |

4.4 |

23.2 |

21.3 |

19.8 |

17.8 |

16.2 |

14.7 |

13.7 |

13.5 |

13.2 |

|

40 |

39 |

37.2 |

34.1 |

31.7 |

28.4 |

26.0 |

23.5 |

21.9 |

21.6 |

21.1 |

According to EN12516

4.5 Nameplate & marking

-Details on the valve:

5.0 Installation

5.1 General notes on installation

The following points should be taken into account besides the general principles governing installation work:

|

ATTENTION! - Remove flange covers if present. -Assurethe packing does not hamper the movement of the stem before installation. - The interior of valve and pipeline must befree from foreign particles. - Note installation position with reference toflow, see mark on valve. - Steam line systems should be designed toprevent water accumulation. -If the pipeline hasenough strength to resist the valve weight and the operation torque, thesupport isn’t needed. Otherwise, the valve should have support point. - Protect valves from dirt during constructionwork. - Connection flanges must mate exactly. - Valve mountings such as actuators, handwheel,hoods must not be used to take external forces, - Suitable materials handling and liftingequipment should be used. - The best installed position ishorizontaland stem isvertical. - The valve must befully open during pressure testing of the pipeline system after installation. |

- Planners / construction companies or operators are responsible for positioning and

installing products.

-The valves are designed for application, not influenced from weather.

- For application outdoor or in adverse environments like corrosion-promoting conditions(sea water, chemical vapours, etc.), special constructions or protective measures are recommended.

-Bellow seal out of media flow path. Especially for pulsating, turbulent flow directly behind

pumps, elbows, junctions etc.

5.2 Installing valves with butt weld ends

-Please note that only qualified persons using appropriate equipment and working in accordance with technical rules are allowed to install fittings by welding.

-The responsibility for this lies with the system owner.

-The valves must be welded in closed position.

5.3 Installing valves with pressure balancing plugs

|

ATTENTION ! -The stop valves must beequipped with pressure balancing plugs if the differential pressures listed in the table(FIG.5)below are exceeded in theclosed state. -Valves with pressurebalancing plugs should be installed so, that the pressure ofthe medium acts onthe plug(pos. 3)and the stem is verticallyupright. |

-Valves with pressure balancing plugs have to be installed with medium flowing over the plug (pos. 3) as indicated by flow direction arrow on valve body.

-Working principles:

When the valve is closed, anticlockwise rotation of the hand wheel lifts the pilot plug (pos.3.1) off the larger balancing plug (pos. 3). This allows the medium to pass through the plug and equalizes the pressure of the medium under the plug (pos. 3). After the pressures have been equalized within the values stated in the table below, the valve can be opened by turning the valve further.

FIG.5

|

Balancing plug |

DN |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

|

Prossure drop |

ΔP |

25bar |

21 bar |

14 bar |

9 bar |

6 bar |

4.5 bar |

3.5 bar |

- Pressure balancing plugs are fully effective only in closed line section.

- The pressures of the medium on either side of the plug cannot be equalized if the medium is discharged into “open air”.

- If adequate pressure equalisation cannot be achieved using a pressure balancing plug, other design solutions must be used instead (e.g. a bypass line).

5.4 Installation data on valves with loose plugs

The data given in point 5.3 applies to the maximum differential pressure. The set pressure

is 0,05 bar. The valve should only be installed in horizontal lines in an upright position.

6.0 Putting the valve into operation

|

-Before putting the valve into operation, checkmaterial, pressure, temperature anddirection of flow.-Regional safety instructions must be adhered to. -Residues in piping and valves (dirt, weld beads, etc.) inevitably lead toleakage. -Touching the valve when it is operating at high (> 50°C) or low (< 0°C)media temperatures can cause injury. -Beforeputting a new plant into operation or restarting a plant after repairs ormodification, always make sure that: - All works has been completed!- The valve is in the correct position for itsfunction. - Safety devices have beenattached. |

Maintanance and maintenance-intervals have to be defined by the operator according to the requirements.

-Observe safety instructions.

- Keep the stem well greased.

|

ATTENTION! -Pay attention, thelubricant must be suitable for the medium. |

- If the stem (pos. 4.2) starts leaking, tighten the bolted gland (pos. 12) until leaking stops (Fig. 7). Replace bonnet at earliest opportunity.

|

ATTENTION! -Retighten the stuffing box packing if required and re-pack it in good time. -For safety reasons werecommend that valves only be repacked when depressurised. -Replace stuffing box packings only after the systemhas cooled down and the pressure in the plant has been relieved. In the case ofcorrosive or aggressive mediums, drain and ventilate the valve before replacingthe packing. |

|

ATTENTION ! Thefollowing points must be observed: -Pressureless pipe system. - Medium must be cool. - Plant must be drained. - Purge piping systems incase of caustic, inflammable, aggressive or toxic medium. |

-Mounting of the bonnet:

- Before reassembling the unit, remember that the bearing surface must be cleaned and 2 new gaskets (pos. 9) must be inserted.

- Set the cover in place.

- Tighten the hexagon nuts evenly crosswise.

- Tightening nuts / screws.

8.0 Guarantee

Guarantee period of valve is 12 months after using, but not exceed 18 months after delivery.

Manufacturer will repair or provide spare parts free of charge on the occurrence of damage due to material, Manufacturer or the damage occurred at correct operation condition during the guarantee period.

9.0 Troubleshooting

-In the event of malfunction or faulty operating performance check that the installation and adjustment work has been carried out and completed in accordance with these Operating Instructions.

-If malfunctions cannot be eliminate with the help of the following table ,the supplier or manufacturer should be consulted.

Bellow seal globe valveTroubleshooting table

|

fault |

Possible cause |

Corrective measures |

|

No flow |

Valve closed |

Open valve |

|

Flange covers not removed |

Remove flange covers |

|

|

Little flow |

Valve not sufficiently open |

Open valve. |

|

Dirt sieve clogged |

Clean / replace sieve. |

|

|

Piping system clogged |

Check piping system |

|

|

Valve difficult to move or cannot be opened |

Stem dry |

Grease stem |

|

Wrong direction of rotation |

Turn in correct direction |

|

|

Lubricating nipple / locking screw tightened |

Loosen lubricating nipple / locking screw |

|

|

Valve stem leaking |

Bellows seal damaged |

Replace top of bellows seal at earliest opportunity! |

|

Gland screw slack |

Tighten gland screw until leakage stops; Replace bonnet at earliest opportunity! |

|

|

Leakage across valve seat |

Valve not properly closed. |

Pull hand wheel tight without tools |

|

Seat / plug) damaged by foreign particles |

Replaced valve or rework sealing surfaces |

|

|

Pressure difference too high. |

Use a valve with pressure balancing plug |

|

|

Medium contaminated (suspended solids). |

Clean valve; Install a strainer upstream of valve |

|

|

Flange broken between valve and piping |

Bolts tightened unevenly; Mating flanges not properly aligned |

Re-align piping and fit new valve |